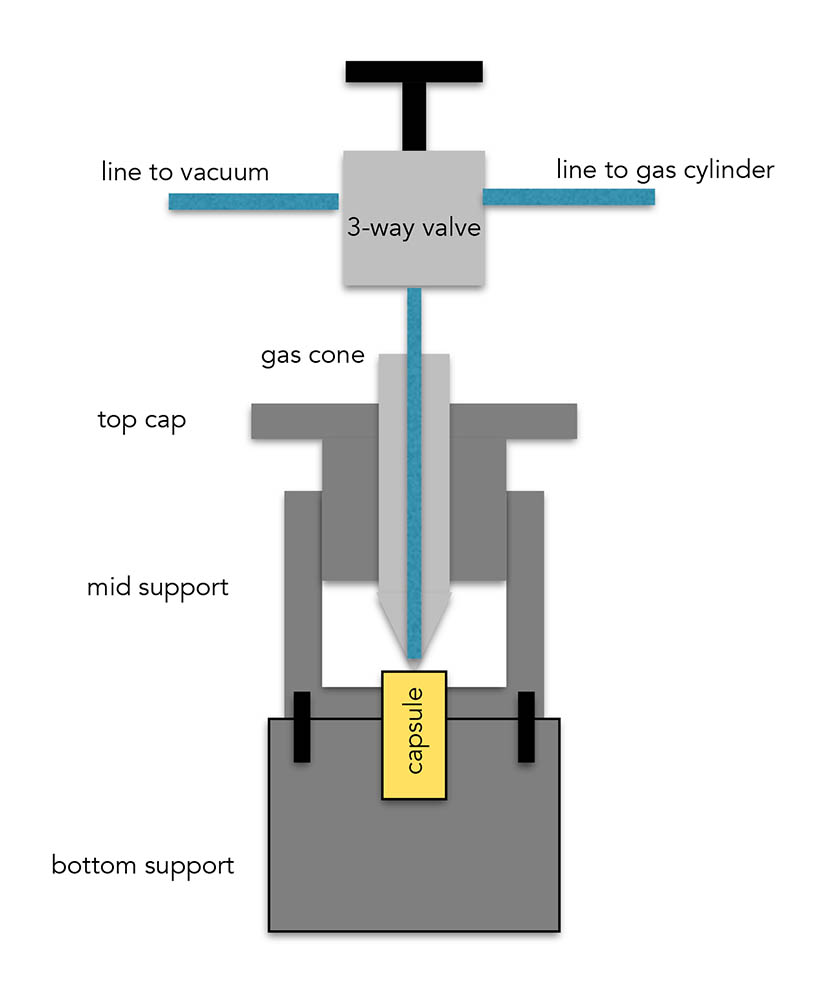

GAS LOADING DEVICE

Depths of the Earth Company’s gas loading device loads gas-phase and gas-phase mixtures directly into precious metal sample capsules for use in high-pressure high-temperature instrumentation, including the QUICKpress.

The original design of this device was conceived by Boettcher et. al (American Mineralogist, Volume 74, page 1383-1384, 1989) for their studies of the solubility of various gases (Ar, Xe, Kr, N2, C02), in silicate melts.

Before Boettcher et al’s invention of the loading device, gas substances were added as liquid- or solid-phase compounds that volatilized or decayed at temperature to release the desired gas phase. The method was labor intensive, often inaccurate, and commonly introduced unwanted elements and ubiquitous water to the system.

KEY FEATURES:

- Fast, easy, and inexpensive to operate

- Standard laboratory vacuum line purges airborne contaminates and evacuates air from the capsule and solid sample

- Gas flow regulation delivers precise quantities of pure gas or gas mixtures to sample capsule container.

TECHNICAL SPECIFICATIONS:

Sample capsule sizes accommodated: 2mm to 10mm OD tubing

Maximum gas pressure of 80 bars for 0.127mm capsule wall thickness

Maximum gas pressure of 100 bars for 0.2mm capsule wall thickness

Equipment included: gas loading device, air/ vacuum 3-way valve and swivel vise with crimping and rubber bumper jaws.

* Customer supplies: vacuum line, gas cylinder, regulator, sample capsule, and welder