EXECUTING EXPERIMENTS

QUICKpress experiments begin with preparation of the starting material. The starting material is often loaded into a chemically-inert metal capsule and sealed using an electric spot welder. Chemical systems not subject to redox reactions and containing low vapor pressure components, such as those of oxide ceramics, may be encased in unsealed capsules. An infinite variety of starting materials and capsules is possible and limited only by the imagination of the researcher. For example, very-high chemical activities of normally gaseous molecules such as oxygen or nitrogen can be obtained by adding materials such as platinum-dioxide or nitrides to the sample capsule.

Executing a QUICKpress experiment involves putting together a furnace assembly and inserting it into the cylinder core. This operation typically requires 5 to 15 minutes depending on the experience of the researcher. The QUICKpress can be stabilized at desired pressure and temperature conditions in another 5 to 10 minutes. Run durations range from several minutes to several days. Quenching the experiment and extraction of the sample requires a final 5 minutes.

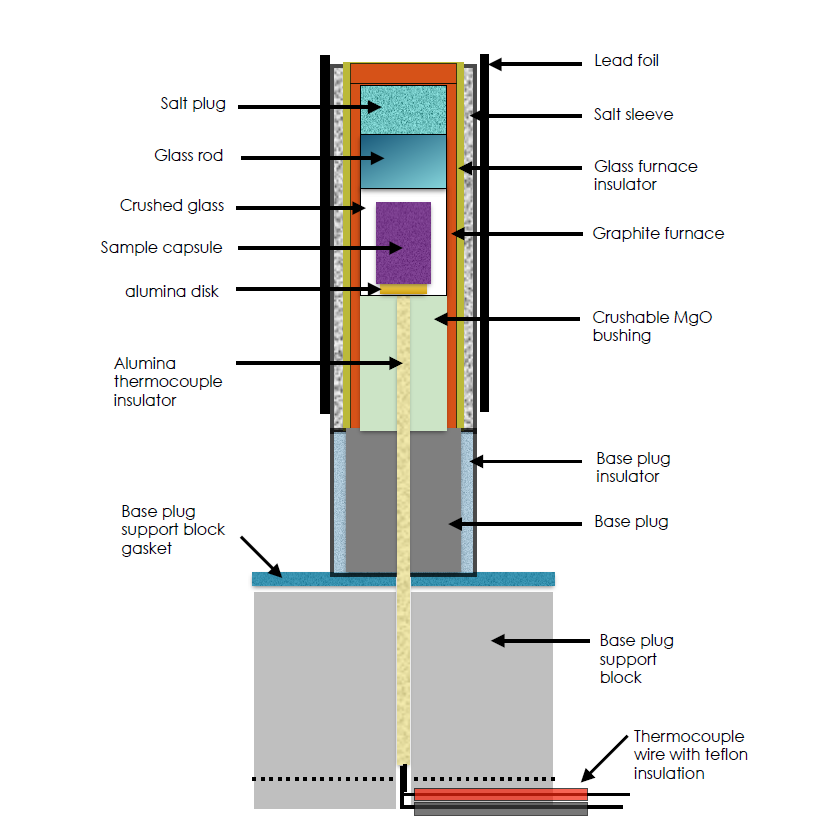

The furnace assembly consists of a set of nested cylinders composed of Al2O3, NaCl, graphite and glass. A glass-sleeve furnace assembly is used for high-tempeature experiments (>1000 °C). Experiments conducted below this temperature employ a thicker salt cell that eliminates the glass sleeve from the furnace assembly.

(Click on image to enlarge)